Detailed Product Description

| Process: |

Wire Cutting |

Material: |

Steel |

| High Precision: |

± 0.005mm Tolerance |

Surface Roughness: |

Ra 0.4-1.6μm |

| Color: |

Black |

Machining Equipmen: |

Wire Cutting Machine |

| Surface Treatment: |

Electroplating, Polishing |

Service: |

OEM/ ODM |

| High Light: |

wire edm cutting, wire cut edm process |

Steel Wire Cutting Processing High Precision Toothed Wheel / Gear

Business Flow:

|

1 Step

|

Clients’ sample or 2D/3D drawings

|

|

2 Step

|

Our engineering department

|

|

3 Step

|

Clients’ requirements and details

|

|

4 Step

|

Sample production

|

|

5 Step

|

Clients receive samples

|

|

6 Step

|

Clients checked and approved

|

|

7 Step

|

Mass production

|

|

8 Step

|

Delivery products

|

|

9 Step

|

Enthusiastic after-sale service

|

Application:

|

·Machinery

|

·Medical

|

·Nut / bolt / screw

|

|

·Electrical

|

·Electronic

|

·Auto / motor / car

|

|

·Building Facilities

|

·Automation Equipment

|

·Communication

|

|

·Office Equipment

|

·Precise instrument

|

·Automobile Engine

|

|

·Optical devices

|

·Washing machine

|

·Sewing Machine

|

|

·Sports Facilities

|

·Sensor

|

·Laser

|

|

·Plumbing

|

·Aerospace

|

·Computer

|

|

·Connector

|

·Printer

|

·Models

|

|

·Lock

|

·LED

|

·Solar

|

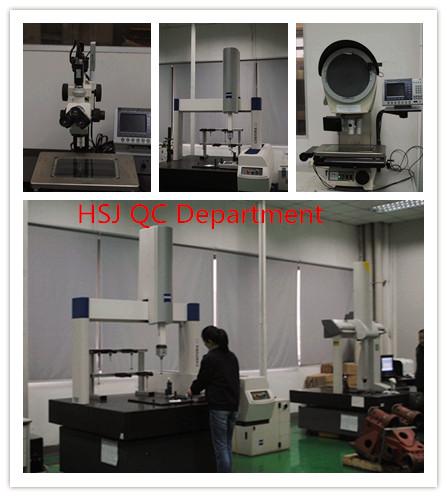

Company Brief Introduction:

We are an ISO9001 approved manufacturer, which specialize in production of

precision parts, we have rich experience in CNC parts, especially sensor, connector,

auto parts, machine parts, computer parts, medical parts, laser parts and so on.

Our mostly machines are imported from Janpan’s Mazak and Okuma,

products are famous for high speed and high precision in intra-industry,

so please believe us we will offer you the best quality, prompt lead time

and competitive price parts.

Why Choose us?

1.Price : Reasonable and competitive price according to your drawings and requirements;

2.Sales Team: Professional engineers and sales service for you at 24 hours, and give you

the best advice to help you save cost; website also supporting in multiple languages;

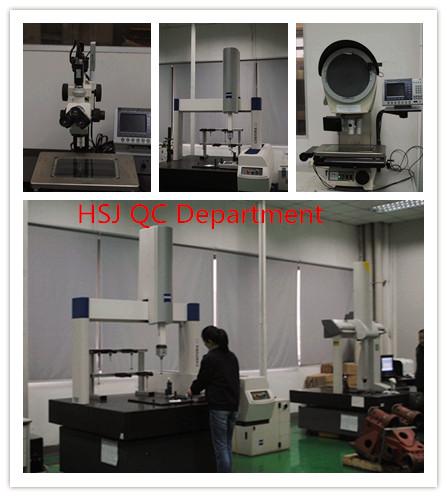

3.Quality Control: All processing and inspection completely follow ISO 2008 rules and system.

Technician will test by themselves during each processing; then QC member will inspect again

before next processing; 100% final inspection for critical dimension before shipping;

4.Rich Experience: Lots of experienced workers with more than 10 years in this field;

Owning advanced processing equipment and detection equipment; Experiences making

a huge variety of items because of the genuinely diverse range of customers we serve;

5.Quality Assurance: Products are sent to you with 100% inspection, which makes you

enjoy the 100% quality guarantee, we will help you repair or redo within 10~15 days

when there any unqualified part;Our factory has passed ISO/SGS 9001 quality certification.

ISO, SGS Rohs certified reports of raw material and finished products can offer to you.

FAQ:

|

|

Question

|

Answer

|

|

1

|

Are you the trading company

or factory?

|

We have our own factory and own advanced

machine equipment.

|

|

2

|

Where is your factory located?

How can I visit there?

|

Our factory is located in Shenzhen city,China.

You can fly to Shenzhen airport;

Clients from home or abroad are warmly

welcome to visit our factory!

|

|

3

|

What`s the production capacity

for your company?

|

Normally can reach 100, 000 pieces per month.

|

|

4

|

How can I get some samples?

|

We are happy to offer you free samples

if you have actual mass production plan.

|

|

5

|

How does your factory do

regarding quality control?

|

Our factory has passed ISO/SGS 9001 quality

certification.ISO, SGS Rohs certified reports of

raw material and finished products can offer to you.

|

|

6

|

How about the delivery time?

|

The delivery time will according to the part quantity,

usually sample will need 7-10 days,

and part production will need 25-30 days!

|

|

7

|

What`s the Scrap rate for the part?

|

Normally, the scrap rate is 3%~4%.However,

we won't send you any scrap part,all the part

will be 100% inspected by our quality

department to make sure no available ones.

|

|

8

|

Is it possible to know how are my

products going on without visiting

your company?

|

We will offer a detailed production schedule

and send weekly reports with digital pictures

and videos which show the machining progress.

|

|

9

|

If you make poor quality goods,

will you refund our fund?

|

As a matter of fact, we wont take a chance to do

poor quality products.Meanwhile, we manufacture

goods quality products until your satisfaction.

|

|

10

|

What we should do if we check out

the part problem?

|

If you have received any unqualified part,

please show us the pictures, after our engineers

and QC department check ,we will choose to help

you repair or redo within 10~15 days according to

rejected quantities.

|

How to contact us?

Click “Contact Now”!

Send your inquiry details with DRAWINGS.